Since Some Polymers and Gels Can Reduce kw Much More than ko or kg, Where Will This Property Be Most Useful?

(Wells and reservoirs where vertical fractures cut through both water and hydrocarbon zones.)

A special property that was reported for some polymers and gels is an ability to reduce permeability to water much more than that to oil or gas.19-27In Ref. 18, we demonstrated that this property is of value only when zones with high hydrocarbon saturation are distinct from the offending water-producing zones. In other words, this “disproportionate permeability reduction” will not mitigate water production from a reservoir that has effectively only one zone. Even if the polymer or gel can significantly reduce permeability to water without affecting the permeability to oil, the average fractional flow of water and oil from that zone must remain the same. If the polymer or gel near a production well allows oil to pass but not water, the water saturation will increase near the gel bank, thus, decreasing the relative permeability to oil until the fractional water and oil flows match the values that existed before the polymer or gel treatment.18Therefore, unless a particular zone is at its irreducible water saturation, a polymer or gel treatment will always cause some loss of oil productivity (i.e., B/D-psi), even if the polymer or gel reduces kwwithout affecting ko. This loss of oil productivity necessarily will be in direct proportion to the loss of water productivity caused in that particular zone.18

The ability of polymers and gels to reduce kwmuch more than ko is most useful when zones of high-oil saturation are being produced along with zones of high-water saturation. If a particular zone produces only oil and the polymer or gel does not affect ko, no reduction in oil productivity will occur. In contrast, for zones that produce only water, water productivity will be reduced in direct proportion to the reduction in kw.

For the credible experimental data reported to date, polymers and gels may reduce kw more than ko, however, they always reduce ko to some extent. In the best cases, Zaitoun and Kohler24reported that adsorbed polymers significantly reduced kw at any given water saturation, while the oil relative-permeability curve was basically unaffected by the polymer. However, the polymer increased the irreducible water saturation, thus lowering the endpoint relative permeability to oil. Therefore, for all practical purposes in zones with high oil saturations, the polymer treatment reduces the effective permeability to oil.

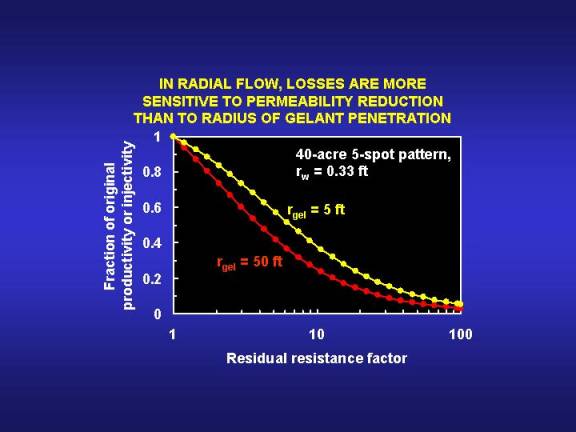

In radial flow, how much reduction in ko can be tolerated? This question is addressed in Fig. 6. Fig. 6 plots the fraction of original injectivity or productivity retained (I/Io) after a polymer or gel treatment as a function of the residual resistance factor (i.e., the permeability reduction provided by the polymer or gel). Fig. 6 applies to a waterflooded reservoir with a 40-acre, 5-spot pattern with a unit-mobility displacement. The wellbore radius was 0.33 ft. Two cases of radii of gelant penetration, rp, are presented-5 ft and 50 ft. A comparison of these two curves reveals that for a given residual resistance factor, the injectivity or productivity losses are not strongly dependent on the radius of gelant penetration.

For radial flow, Fig. 6 reveals that relatively small residual resistance factors can cause significant injectivity or productivity losses. For example, for a gel radius of 50 ft, a Frr value of 2 causes a 27% loss in I/Io, while a Frr value of 10 causes a 75% loss. Both of these losses might be considered unacceptable if these are oil zones. Thus, in unfractured wells, hydrocarbon residual resistance factors (Frro) must be small. (Depending on the rock and the gelant system, these low Frro values may be difficult to obtain in a predictable and controllable manner.28)

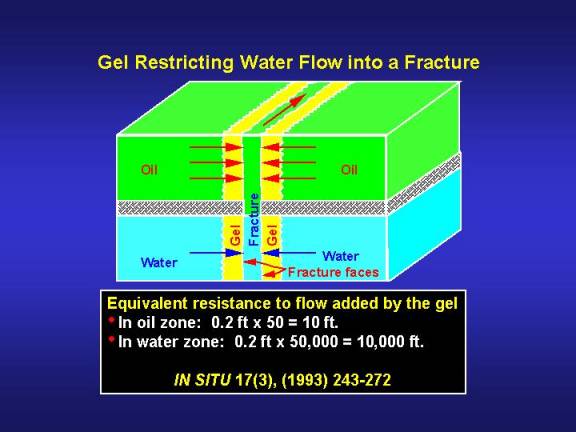

The disproportionate permeability reduction may be of greater value in treating production wells where vertical fractures cut through both water and hydrocarbon zones25 (see Fig. 7). When a gelant is injected into a fractured production well, hopefully, it will propagate a large distance down the length of the fracture while leaking off a very short distance into the porous rock. Assume that the gelant leaks off 0.2 ft into both the oil and water zones. Also, assume that the gel reduces ko by a factor of 50 while reducing kw by a factor of 50,000. (We are aware of a gel with these properties.25) Upon first consideration, a Frro value of 50 might appear to be prohibitively high. However, because of the short distance of leakoff in this example (0.2 ft), the gel only adds the equivalent of 10 feet of additional rock that the oil must flow through to enter the fracture (i.e., 0.2 ft x 50). In contrast, for the water zone, the water must flow through the equivalent of 10,000 ft of additional rock to enter the fracture (i.e., 0.2 ft x 50,000). Thus, the gel can substantially reduce water production without significantly affecting oil productivity