Since Chemical Propagation and Retention Rates Vary with Permeability, Can These Differences Be Exploited to Eliminate the Need to Protect Hydrocarbon-Productive Zones During Gelant Placement?

(No, based on evidence to date. However, this may be possible in the future, depending on research progress.)

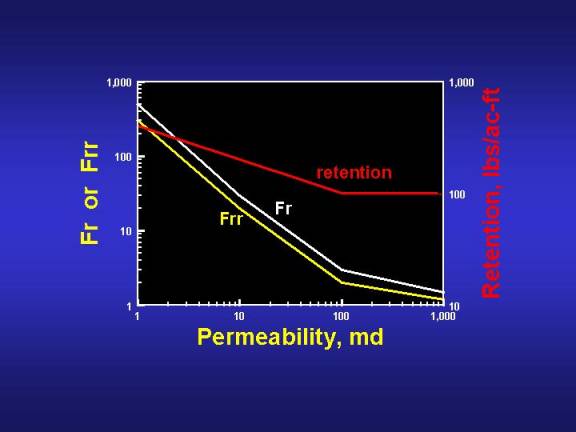

For many years, people have recognized that polymer and gel resistance factors, residual resistance factors, and chemical retention values in porous media increase with decreasing permeability.5-9 Fig. 12 provides example data that were reported by Vela et al.5 for polyacrylamide solutions.

Since resistance factors and retention values increase with decreasing permeability, can this behavior be exploited to minimize polymer or gelant penetration into low-permeability zones? Also, once the polymer or gelant has been placed, will the treatment ultimately improve the flow profile? Using data such as those in Fig. 12, calculations can be performed to answer these questions. Table 2 summarizes the results from calculations made using Fig. 12 and the methods described in Ref. 1. These calculations reveal that the permeability dependence of the resistance factor and retention values does, indeed, reduce the degree of penetration, (rp2-rw)/(rp1-rw). With these factors taken into account, the degree of penetration was 0.082. For comparison, if Fr=4 and the retention was the same in both layers, the degree of penetration would have been 0.311. The last column in Table 2 reveals that in spite of the apparently favorable placement properties, the treatment caused a much greater injectivity loss in the low-permeability layer than in the high-permeability layer. This result occurred because the residual resistance factor was much greater in the low-permeability rock than in the high-permeability rock.

| Layer | k,md | Fr | Frr | retention, lbs/ac-ft |  |

injectivity retained | |

| 1 | 137 | 4 | 2.4 | 75 | 68% | ||

| 2 | 12 | 51 | 45 | 772 | .082 | 32% |

Other researchers32-35 have suggested promising new concepts that may help to limit the distance of polymer penetration or permeability reduction in less-permeable zones. Certainly, these ideas should be pursued and encouraged. However, we must remember that the effectiveness of a given blocking agent depends on its permeability-reduction properties, as well as its placement properties. Whenever a promising new concept is suggested, simple screening calculations (like those illustrated in Table 2) should be performed to confirm that the idea can actually improve flow profiles. Additional work in this area can be found in Refs. 1, 4, 8, 9, 11, and 29.