In Radial-Flow Systems, Can the Rheology of Existing Non-Newtonian Polymer Solutions Provide a Better Placement than That for Gelants with Water-Like Viscosities?

No.

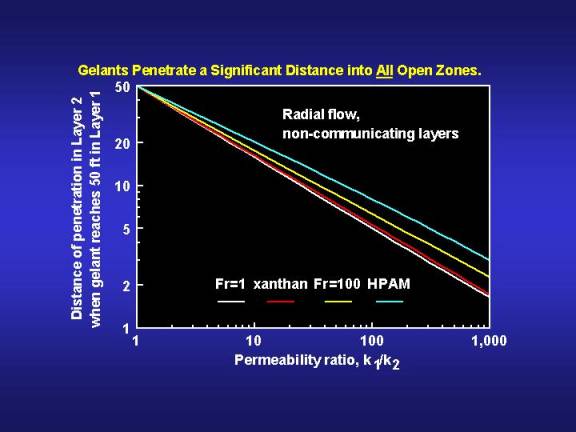

A basic principle of fluid displacement is that the efficiency of the displacement increases with decreasing mobility (or increasing viscosity) of the displacing phase.1,3 This is also a basic principle of polymer flooding. For a given distance of viscous-fluid penetration into a high-permeability zone, the distance of penetration into less-permeable zones becomes greater with increased viscosity or resistance factor (Fr) of the injected fluid.1 This concept is illustrated in Fig. 9 for a gelant displacing water in a radial system with non-communicating zones The y-axis in Fig. 9 plots the radial distance of gelant penetration in a low-permeability zone (Layer 2) when the gelant reaches 50 ft in the most-permeable zone (Layer 1). This quantity is plotted versus the permeability contrast, k1/k2. Fig. 9 shows that at any given permeability contrast, the degree of gelant penetration (i.e., the distance of penetration in a low-permeability zone relative to that in the most-permeability zone) is greater for a gelant with Fr=100 than for a gelant with Fr=1.

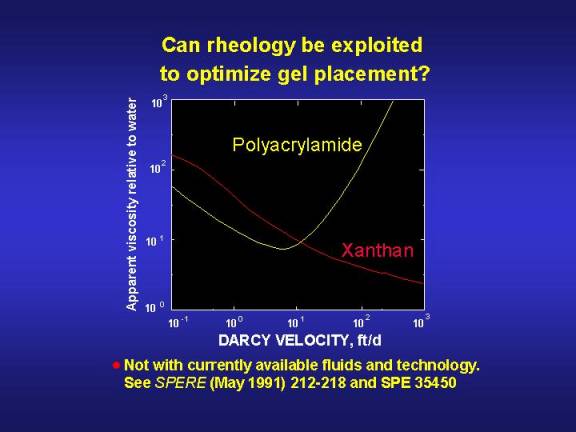

Fig. 9 also shows that for any given permeability contrast, a gelant with Fr=1 provides a lower degree of penetration than non-Newtonian polyacrylamide or xanthan solutions. (Fig. 10 illustrates the non-Newtonian rheology of polyacrylamide and xanthan solutions.) In Refs. 4 and 29, we examined whether the non-Newtonian rheology of existing polymeric gelants can be exploited to optimize gel placement. In Ref. 4, we considered eight different rheological models that have been used to describe the behavior of polyacrylamide and polysaccharide solutions in porous media. We considered shear-thinning models, shear-thickening models, and models that showed combined shear-thinning and shear-thickening behavior. All of the models were examined during simulation of placement behavior in parallel linear corefloods, parallel radial corefloods, fractured wells, and wells without fractures. The analysis revealed that in radial flow, for all models tested, the rheology of existing polymeric gelants will not allow a placement that is superior to that for a gelant with a water-like viscosity or resistance factor (i.e., Fr=1).

During water injection after gel placement, an apparent non-Newtonian behavior can be observed.8,9,29 An analysis of this behavior that has been reported to date does not suggest that it will eliminate the need to protect hydrocarbon-productive zones during gelant placement.11,29